أرسل لنا رسالة

scrap charger for induction furnace

Vibratory Feeder Charger for Induction

A vibratory feeder is mounted on a trolley that moves on rails to feed the furnace. A sturdily built hopper receives and stores the charge material to be fed to the furnace. The feeder vibration ensures that the charge is well spread in the

获取价格

Induction Furnace Charging Systems - Inductotherm Corp.

50 Tons Scrap Charging Car for Induction Furnace

2024/11/11 50 Tons Scrap Charging Car for Induction Furnace, Find Details and Price about Induction Furnace Scrap Steel from 50 Tons Scrap Charging Car for Induction Furnace - FUJIAN XIN YANCHUANG

获取价格

Furnace Charging - Foundry Projects

Melting Time Prediction Model for Induction Furnace

2021/1/20 The first phase of steelmaking using induction furnace melting is the scrap charging which could be done manually or by mechanical systems depending on the size and

获取价格

Vibratory Scrap Feeder / Furnace Charger - Filtech International

To meets the market needs Filtech International introduced its state of art machine “Vibratory Furnace Feeder/Charger” today’s most technologically advanced induction furnace charger.

获取价格

GOOD PRACTICE GUIDE - Foundry Gate

2018/7/10 EFFICIENT MELTING IN CORELESS INDUCTION FURNACES. This Guide is No. 50 (revised) in the Good Practice Guide Series and provides advice on practical ways of

获取价格

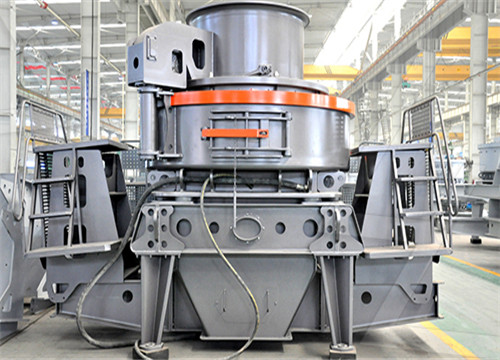

Vibration Charging Car for Casting Electric

2024/10/2 Vibration Charging Car for Casting Electric Furnace, Find Details and Price about Induction Furnace Scrap Steel from Vibration Charging Car for Casting Electric Furnace - FUJIAN XIN YANCHUANG TECHNOLOGY

获取价格

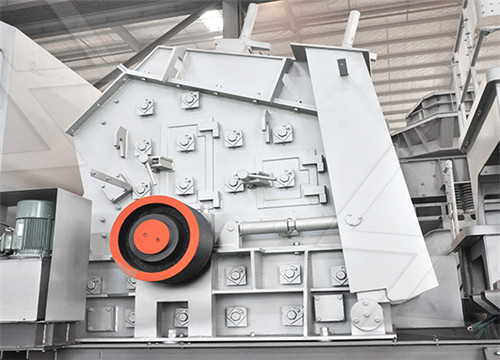

Furnace Charger Mobile Charging Machine

Furnace charging machines can safely and efficiently transfer molten (“charged”) materials to furnaces to streamline foundry operations. CYRUS Mobile Charging Machines are a versatile and durable solution for all your furnace loading and

获取价格

Induction Furnace Selfdumping Scrap Charger

2024/11/4 Induction Furnace Selfdumping Scrap Charger Trolley Air Pollution Control. Contact Now. Inquiry Basket. Find Similar Items. High Vacuum Induction Melting Furnace for Metal Sample Research in Laboratory.

获取价格

Furnace Charger Mobile Charging Machine

When working with metals in a foundry, hazardous materials such as molten metal and scrap need to be safely transferred to and from furnaces throughout the process. Furnace charging machines can safely and efficiently transfer

获取价格

Development of Scrap Charge Maximization Program

2024/4/30 commonly used foundry melting furnaces include: crucible furnaces, the cupola furnace, induction furnaces, and electric arc furnaces. A crucible furnace is a melting unit that uses a refractory crucible which contains the metal charge. The charge is heated via conduction of heat through the walls of the crucible. The heating fuel is typically

获取价格

Design Analysis of an Electric Induction Furnace for

2021/4/12 The induction furnace consists basically of a crucible, inductor coil, and shell, cooling system and tilting mechanism. The crucible is formed from refractory material, which the furnace coils is lined with. This crucible holds the charge material and subsequently the melt. The choice of refractory material depends on the type of charge, i.e.

获取价格

Effect of Scrap Quality on Coreless Induction Melting Time

2022/2/6 For example, purchasing relatively inexpensive scrap metal units can reduce raw material costs overall, but at the same time can have a significant and deleterious effect on furnace efficiency. In the past 60 years, the melting of various ferrous charge metals in coreless induction furnaces has changed. As the quality of the metallic charge ...

获取价格

Furnace Charging Solutions For Steel Plants - India

We offer a variety of systems for assembling and moving scrap and other charge materials to the melt deck and into the furnace. These systems include charge buckets, belt conveyors and vibratory, pivoting, traversing and holding conveyors. Manual charging and most magnets have difficulty keeping pace with large induction furnaces that are able ...

获取价格

Development of charge calculation program for target

2015/12/18 of scrap charge for optimization is incorporated to enable the user simulates changes and manipulates scrap charge in the furnace before ferro-alloys and carbon additives are charged depending on the foundry practice or target standard. This also helps in the decision of the furnace engineer while requesting scrap from the yard.

获取价格

MANUFACTURING PROCESS OF INDUCTION FURNACE

2018/11/17 size Scrap bundles will be Lifted and Transported by Over head cranes and fed to Induction Furnace. Scrap/ sponge iron, fluxes, Ferro alloys are melted in an Induction furnace, wherein electric current is passed through it. In the Induction Melting Furnace the scrap melts at temperature of about 16500C. When the total charge is melted into hot ...

获取价格

Design Analysis of an Electric Induction Furnace for Melting Aluminum Scrap

2005/10/1 A muffle furnace using locally available materials was developed. The muffle furnace consists of an external casing, heating chamber, heating element, charging door, and temperature controller.

获取价格

Melting and treatment of steel for casting - ScienceDirect

2000/1/1 There are many variations of the basic arc steelmaking process. The practice used depends on the type of steel to be made and the quality of the scrap steel used for the charge. Induction furnace melting The medium frequency coreless induction furnace (Fig. 4.5) is the most flexible steel melting unit and is widely used in steel foundries.

获取价格

Induction Furnace and Important Operational

2015/2/14 Induction furnace, liquid steel, power, scrap, tapping. energy, Induction Furnace and Important Operational Aspects ... For better and efficient operation of melting in induction furnace, raw material charge must fulfill the

获取价格

Vibration Charging Car for Casting Electric

2024/10/2 Vibration Charging Car for Casting Electric Furnace, Find Details and Price about Induction Furnace Scrap Steel from Vibration Charging Car for Casting Electric Furnace - FUJIAN XIN YANCHUANG TECHNOLOGY

获取价格

DRI-HBI Induction Furnace Application PDF

2018/10/23 The document discusses direct reduced iron (DRI) melting in an induction furnace. DRI is characterized by high porosity, low conductivity, and oxygen content. It is a suitable replacement for steel scrap which has short

获取价格

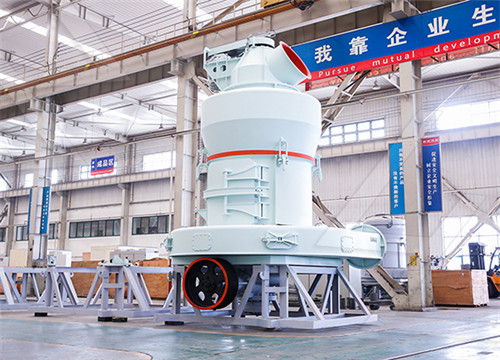

Manufacturers of Vibratory Furnace Charger as Vibratory Sale

Vibrating Furnace Chargers consists of a vibrating feeder mounted on a moving trolley with a storage hopper mounted above the feeder. Our company make vibratory furnace chargers basically comprise of the following parts. Vibrating Feeder suitable for delivering required capacity. Storage hopper of required capacity.

获取价格

Production of Steel in Induction Furnace - IspatGuru

2019/5/26 Fig 1 Major thermal losses in induction furnace. The factors which affects the consumption of electrical energy in the furnace (Fig 2) include (i) dirt going in the furnace with scrap, (ii) rusty charge material, (iii) low bulk density of the scrap, (iv) recarburizing of steel when the steel is almost ready, (v) not using full power for melting, (vi) excessive formation of slag,

获取价格

More Powerful Induction Furnaces and Inverters

2011/1/20 Digitalization Cuts Scrap, Saves Costs. Sept. 19, 2024 . Jill Lehmann Dreamstime. Issues and Ideas. Jack Palmer, 1953-2024. ... after the metal has reached the proper temperature and successive melts are started using unheated or preheated solid charge materials. Although this process has always been typical of smaller induction systems ...

获取价格

50 Tons Scrap Charging Car for Induction Furnace

2024/11/11 50 Tons Scrap Charging Car for Induction Furnace, Find Details and Price about Induction Furnace Scrap Steel from 50 Tons Scrap Charging Car for Induction Furnace - FUJIAN XIN YANCHUANG TECHNOLOGY CO., LTD. ... Induction Furnace Charger Vehicle, Ladle Hook, Ladle, Induction Furnace Dedusting Project, Cutting Machine, Baler Pressing, ...

获取价格

Iron making in induction furnace for casting steel billets

2023/7/4 An induction furnace is an electrical furnace in which the heat is applied by induction heating of metal for the production of steel [1].Since no arc or combustion is used, the temperature of the material is no higher than required to melt it; this can prevent loss of valuable alloying elements [2].It is well known that, during melting in induction furnace all refining

获取价格

Medium Frequency Furnace Manipulator Manufacturer,

Medium Frequency Furnace Manipulator, Ladle Vehicle, Induction Furnace Charger Vehicle, Ladle Hook, Ladle, Induction Furnace Dedusting Project, Cutting Machine, Baler Pressing, Metallurgical Equipments, CCM ... mediate frequency furnace manipulator: 300 Sets: Scrap charger vehicle: 230 Sets: intermediate frequency induction furnace dedusting ...

获取价格

Channel Induction Melting Furnaces - Ajax TOCCO

6 之 Induction Channel Melting Furnaces. Induction channel furnaces are designed to fit most ferrous alloy foundry needs and are most well known for their continuous melting capabilities, maximum efficiency, flexibility (they can be used as melters, holders, off-peak melting, and have the advantage of holding large volumes of metal required for large or

获取价格