أرسل لنا رسالة

Chemical process of concrete crushing

Role of Impact and Compression-Based Crushing on the Physical, Chemical ...

2024/2/26 The main objective of this article is to study the role of the widely adopted crushing techniques, viz., impact and compression, on the physical, chemical, and morphological properties of recycled concrete aggregates (RCA).

获取价格

Concrete Crushing - an overview ScienceDirect Topics

2010/8/7 Concrete crushing (ductile failure) This form of failure is an exemplary flexure mode recorded in conventional RC beams occurs through crushing of concrete by the side of

获取价格

Role of Impact and Compression-Based Crushing on the Physical, Chemical ...

2024/2/27 Abstract. The main objective of this article is to study the role of the widely adopted crushing techniques, viz., impact and compression, on the physical, chemical, and

获取价格

Cement - Extraction, Processing, Manufacturing

2024/9/26 There are four stages in the manufacture of portland cement: (1) crushing and grinding the raw materials, (2) blending the materials in the correct proportions, (3) burning the prepared mix in a kiln, and (4) grinding the burned

获取价格

Role of Impact and Compression-Based Crushing on the Physical, Chemical ...

2024/5/1 Semantic Scholar extracted view of "Role of Impact and Compression-Based Crushing on the Physical, Chemical, and Morphological Characteristics of Recycled Concrete

获取价格

Influence of multi-stage processing and mechano-chemical

2023/12/15 In order to minimise the old cement fractions and increase the quality, this paper studies the effect of concrete incorporating multi-stage processed RA from demolished

获取价格

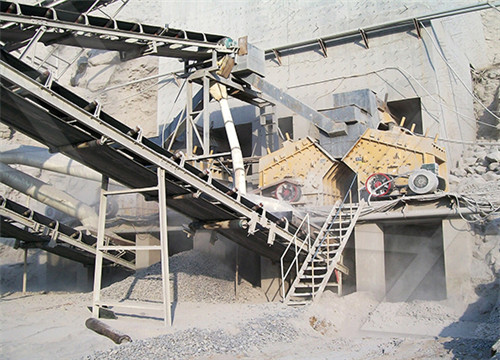

Concrete aggregates properties crushed by jaw and impact secondary crushing

2019/1/1 This paper compares the use of jaw and impact secondary crushing for producing coarse recycled aggregates from concrete wastes, obtained from road pavement and

获取价格

Chemical Extraction and Mechanical Crushing Method for

2010/10/20 A new fine aggregate recycling process from waste concrete using high-pressure carbon dioxide (CO2) solution is proposed. The basic mechanism of the recycling

获取价格

High-quality coarse aggregate recycling from waste concrete

2020/1/29 This study presents a liberation process for recycling high-quality coarse aggregates from waste concrete by impacting with steel grits.

获取价格

Chemical Extraction and Mechanical Crushing Method for

2010/10/20 A new fine aggregate recycling process from waste concrete using high-pressure carbon dioxide (CO2) solution is proposed. The basic mechanism of the recycling

获取价格

Chemical recycling and use of various types of concrete waste

2021/2/15 5.1. Water treatment by waste concrete. Ca 2+ ions that are leached from the concrete waste can react with phosphorus to form calcium hydroxyapatite (HAP) precipitate, as shown in Eq. (4) (Mohara et al., 2009). (4) 10Ca 2+ + 6PO 4 3− + 2OH − → Ca 10 (PO 4) 6 (OH) 2 Waste concrete has been used as a sorbent to remove phosphorus from wastewater from a

获取价格

Role of Impact and Compression-Based Crushing on the Physical, Chemical ...

2024/2/27 The main objective of this article is to study the role of the widely adopted crushing techniques, viz., impact and compression, on the physical, chemical, and morphological properties of recycled ...

获取价格

Influence of multi-stage processing and mechano-chemical

2023/12/15 Florea [1] investigated the effect of multi cycle jaw crushing (10 crushing cycles) on RA and it was found that additional amount of cement paste was recovered by increasing number of crushing cycles. However, the additional number of crushing cycles were more energy consuming than the ordinary crushing process.

获取价格

The simulation of the fine crushing process of basalt

The simulation of the fine crushing process of basalt-manufactured sand and its morphology's effect on the early age evolution of concrete ITZ ... Therefore, in this paper, the physical and chemical properties of basalt were analyzed firstly through molar hardness testing, compressive strength testing, density testing using the boiling exhaust ...

获取价格

Evaluating the Impact of Crushing Process on Strength

2023/4/3 Evaluating the Impact of Crushing Process on Strength Characteristics and Leachability of Cement-Stabilized Dredged Sediment ... properties and leachability were mainly attributed to the fact that the strong cementation bonding was destroyed by the crushing process, weakening the soil structure and raising the potential for release of elements ...

获取价格

High-quality coarse aggregate recycling from waste concrete

2020/1/29 The techniques used in the above studies were mainly chemical methods, mechanical crushing methods, or the combination of heating and mechanical crushing methods. However, these methods involved a complicated treatment process, the heating method consumed a large amount of energy, and the pollution from the chemical method was heavy

获取价格

Role of Impact and Compression-Based Crushing on the Physical, Chemical ...

2024/2/26 However, due to cleavage failure in compression crushing, coarser RCA with higher concentrations of blade and disc-shaped particles and higher HCMP content were produced. The fracture failure associated with compression crushing led to the production of less amorphous concrete fines with ∼ 45 % higher quartz content. However, the fineness of ...

获取价格

Durability of Recycled Concrete Aggregates Prepared with ...

2022/8/22 When the demolished concrete is heated to around 300 °C, dehydration causes the cement paste to become brittle . In these treatment processes, mechanical crushing is followed by chemical soaking and finally by thermal roasting of

获取价格

Chemical Extraction and Mechanical Crushing Method for

2010/10/20 A new fine aggregate recycling process from waste concrete using high-pressure carbon dioxide (CO2) solution is proposed. The basic mechanism of the recycling process is extraction of calcium from a hydrated cement component, which reacts readily with acid. Calcium extraction would be effective in promoting the separation of hydrated cement

获取价格

Cement Manufacturing Process: Know Extraction, Processing

2024/9/10 Steps of Cement Manufacturing. The steps involved in cement manufacturing are as follows: Quarrying: Raw materials such as limestone and clay are extracted from quarries or mines.; Crushing and Grinding: The extracted raw materials are crushed and ground into a fine powder.; Blending: The crushed and ground raw materials are blended in specific proportions

获取价格

On-Site Concrete Crushing - Priestly Demolition

On-Site Concrete Crushing and Recycling Process. ... Chemical additives in the tank cause certain materials to float to the top of the tank, leaving only crushed concrete at the bottom. Recycling. The final step is to recycle and reuse the

获取价格

Leading Supplier of Cement Plant Equipments

2024/10/29 At present, it has completed over 60 new dry-process cement clinker production lines of various sizes (300-8000 tons/d), more than 10 pure low temperature waste heat power generation projects for cement clinker

获取价格

Modification of Recycled Concrete Aggregate

2023/11/13 The differences in physical properties, chemical properties, and mechanical properties between reclaimed concrete aggregate and natural aggregate are discussed in this paper. In this paper, the commonly used

获取价格

Concrete crushing based on the high-voltage pulse

2021/9/1 In this paper, the theory of concrete crushing is studied based on the technology of electrohydraulic effect. 2. The model of HVPD concrete crushing. Based on the characteristic of the impact load caused by high-voltage impulse, the whole process of the concrete beam has been simulated and analyzed by the ANSYS/LS-DYNA software. 2.1. Material model

获取价格

(PDF) Study and Review of Ordinary Portland Cement

2021/8/26 This research aimed to investigate the environmental, economic, and functional performances of ordinary portland cement (OPC). In short, we discussed the definition, the chemical composition and ...

获取价格

Role of Impact and Compression-Based Crushing on the Physical, Chemical ...

2024/2/26 However, due to cleavage failure in compression crushing, coarser RCA with higher concentrations of blade and disc-shaped particles and higher HCMP content were produced. The fracture failure associated with compression crushing led to the production of less amorphous concrete fines with ∼ 45 % higher quartz content. However, the fineness of ...

获取价格

Concrete aggregates properties crushed by jaw and impact secondary crushing

2019/1/1 A two-crushing process can be found in European recycling plants, while the choice of a secondary crusher often relies on qualitative criteria such as coarse and fine RCA recovery fractions. ... Crushing mechanisms, concrete porosity induced by cracks, ... The chemical composition was used to indicate the content of each phase present in the ...

获取价格

Research on crushing and recycling of waste concrete

2020/3/21 Concrete itself, and issues relating to the recycling and management of reinforced concrete waste, are highly relevant, especially when urban expansion is being achieved by increased building ...

获取价格

Energy Efficiency Measurement of Mechanical Crushing

2024/6/28 The results demonstrate that the crushing efficiencies of ore crushing particles, raw material crushing particles, and cement crushing particles can respectively reach 80.7%, 70.15%, and 80.27% ...

获取价格

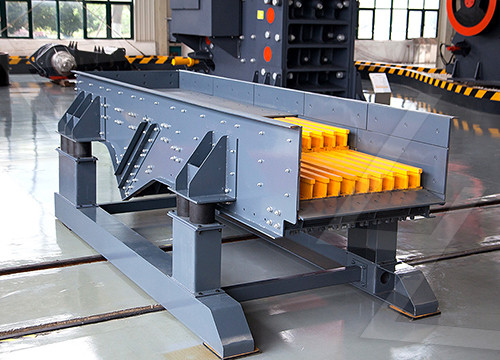

Everything you need to know about Crushers in Cement

The three fractions < 400 mm, < 100 mm and < 30 mm can be taken as a rough classification for the different grinding processes. CRUSHING SYSTEMS AND APPLICATION . General . For process technological, cost reasons and insofar as allow by the properties of the raw material. One should try to accomplish all crushing activities in one machine, a ...

获取价格