أرسل لنا رسالة

manufacture static air separator for coal mill

Air separators Qlar

Our air separators adapt to your process - not the other way around. Whether integrated into our mills or installed as standalone process equipment, we design and manufacture various types of air separators that can be used for a wide

获取价格

Industrial Solutions sepol high-efficiency separator

2022/11/21 Whether it is a roller mill for coal, limestone, granulated blast fur- nace slag or cement grinding, the sepol ® QM or RM high-efficiency separator is integrated into the mill

获取价格

AIR SEPARATORS - INFINITY FOR CEMENT EQUIPMENT

2017/5/22 Static Grit Separators. These permit the separation of large particles from the material being transported in the mill air sweep. These are common on vertical roller mills, air

获取价格

Separators - KHD Humboldt Wedag

Dry Coal Separators Dry Coal Processing

The FGX technology provides an innovative and cost-effective dry coal processing process that integrates the separation principles of an autogenous medium separator and a conventional table concentrator. Three product

获取价格

Air / Material Separators Kongskilde Industries

Kongskilde separators are strategically positioned at the discharge end of conveying systems, such as stationary compactors, balers, or containers, ensuring efficient material separation from the conveying air flow.

获取价格

Rolling Bearings in Air Separators of Vertical Grinding Mills

2019/5/24 The MPS vertical grinding mills built by Babcock Hitachi Europe are designed for maximum productivity and are in use in numerous coalfired power plants.

获取价格

High efficiency dynamic separator - Fives - PDF Catalogs

The principle of separation lies in the use of centrifugal force generated by way of a flow with vortex (cyclone and derivatives, etc.) for static classifiers or a rotating turbine for dynamic

获取价格

Performance of the static air classifier in a Vertical Spindle Mill

2016/8/1 In order to investigate the classification performance of static air classifier in an industrial Vertical Spindle Mill (VSM), sampling ports were drilled on the mill shell and new on

获取价格

Coal mill dynamic separator- Jiangsu Jida machinery manufacture

JD series combined dynamic separator is a new generation of high performance separator integrating coarse powder separation and horizontal eddy current powder separation, which is

获取价格

A unified thermo-mechanical model for coal mill operation

2015/11/1 Further, the performance and availability of the plant is influenced by several faults occurring in the milling system and various mill related factors such as incorrect fineness, improper air/fuel ratios, coal hang up at the mill inlet, overloading, fire /explosion, and wear of milling components (Maloney, Benson, Tous (1981), Sathyanathan ...

获取价格

AIR SEPARATORS - INFINITY FOR CEMENT EQUIPMENT

Static Grit Separators. These permit the separation of large particles from the material being transported in the mill air sweep. These are common on vertical roller mills, air swept coal mills. One of the largest units in service can found on Alpena’s

获取价格

sbm/sbm mill grit static separators.md at main sili2023/sbm

Host and manage packages Security. Find and fix vulnerabilities

获取价格

seal air fan coal mill – Grinding Mill China

2013/4/1 What is seal air fan for coal mills – The QA wiki. Seal air fan is for avoiding foreign material entry in to the roller – by damaging the seals.The seal air fan flow is passing between the seal air ring and the cover » More detailed ID Fans, Blower, Bag Filter System, Damper, FD Fan, Axial Fans. Induced draught (ID), Forced draught (FD), Primary Air,

获取价格

Performance of the static air classifier in a Vertical Spindle Mill

2016/3/1 The multi-component models incorporate the effects of size and ash distribution in coal feed, air and coal flow rate and power drawn by the mill. Both models utilise the size-by-size density ...

获取价格

Air Separators: Introduction To Cement Manufacturing PDF Mill ...

2024/5/26 This document discusses cement manufacturing and air separators. It describes different types of separators including first, second, and third generation separators as well as static grit separators. It provides details on the components and operation of static grit separators. The document also covers control of separators, including adjusting vanes to control fineness,

获取价格

brochure sepol separator - myPolysiusService

2024/2/14 The separation process takes place by means of fresh air and filter separation, or by means of cyclone circulating air. The sepol® separator has also proven an ideal solution for plant conversions and modernization projects with limited space con-ditions, thanks to its modular design and flexible arrangement possibilities. Layout of a ball mill/

获取价格

Bowl Mill Coal Pulverizer - COAL HANDLING PLANTS

1. The hot air dries the coal. 2. The hot air is used for transportation of the recirculating coal within the mill and also for transporting the coal from the pulverizer to the furnace. As the coal is continuously reduced in size, the smaller/lighter particles are swept from the bowl by the hot air.

获取价格

grinding system with static and dynamic separators - Grinding Mill

2013/4/21 » process flow chart for manufacturing of detergents » mineral purifying plant for tantalite » how does coal mill separator works » production cost of crusher run gravel » proo file grinding wasino gls 80a » magisa s.r.l stone cutting machine price

获取价格

Sewage Treatment Plant Manufacturer, Dissolved Air

Sewage Treatment Plant Supplier, Dissolved Air Floating Machine, Inclined Plate Clarifier Manufacturers/ Suppliers - Qingdao Yimei Environment Project Co., Ltd. Menu Sign In. Join Free For Buyer. Products Suppliers ... 30m3/H Air Flotation Separator for Oil Waste Water Treatment Project FOB Price: US $2,000-32,000 / set. Min. Order: 1 ...

获取价格

Coal Mill in Cement Plant Vertical Roller Mill

The most used coal mills in cement plants are air-swept ball mills and vertical roller mills. At present, most cement plants use coal as the main fuel in the clinker production process. The standard coal consumed by the new dry process for

获取价格

(PDF) CFD Modeling of MPS Coal Mill for

2009/1/1 The aerodynamics within a reduced scale model of a vertical spindle coal mill static classifier are investigated to provide data for improving classifier particle separation predictions and the ...

获取价格

VRM – AMCL Machinery Limited

In-Built Reliability for Cement Plant Application: Raw Material, Cement, Slag, Coal and Minerals. In May 2019, AMCL signed an exclusive Licensing Agreement for the design, manufacture, erection, commissioning and after sales service with

获取价格

Coal Mills Pulverizers Tube Mill Assembly – NS Engineering

2018/4/9 Complete RP Bowl Mills for coal crushers used in Thermal Power plants up to 660 MW. Components include air inlet housing, separators body, separator top and involves heavy fabrication and critical machining with both static and dynamic separator for various pulveriser sizes.

获取价格

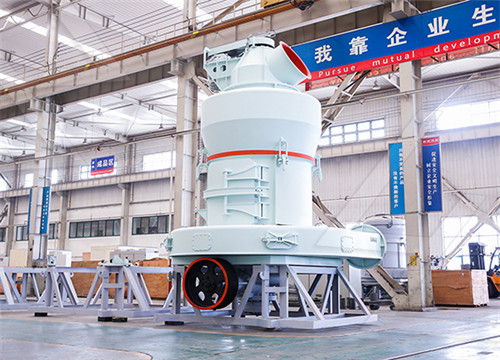

Cement Separator – Cement Mill Separator Cyclone Air Separator

Its powder selection efficiency can reach 80-85%. Besides, we also provide other types of cement separators, such as TZX series cement separator, TS series cement separator, and MX series cement separator. Cyclone Air Separator Working Principle. The circulating air of the cement cyclone separator is generated by the air blower.

获取价格

Air separators Qlar

Whether integrated into our mills or installed as standalone process equipment, we design and manufacture various types of air separators that can be used for a wide range of applications and capacities. With both static and dynamic classifiers available and flexible operation options, we work with you to find the best solution for your ...

获取价格

Coal separator, Coal classifier - All industrial manufacturers

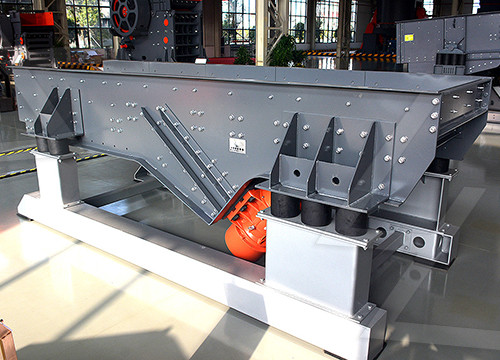

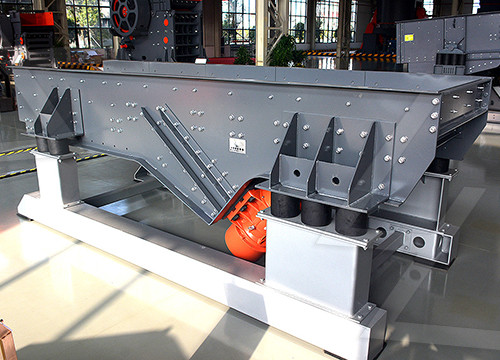

Length: 50 mm - 3,050 mm Width: 100 mm - 6,710 mm Weight: 20 kg - 17,465 kg. Eriez CrossFlow Separator is a highly efficient hydraulic classifier for the separation of material based on particle size, shape and/or density. This technology can

获取价格

Separators - KHD Humboldt Wedag

From lowering costs to reducing environmental footprint, separators need to achieve high efficiency while lowering energy consumption. At KHD, we have a long history of innovation in separator technology. That tradition is part of our DNA and the basis for our continued technical development. Serving a range of applications from raw materials to cement, as well as in the

获取价格

Modeling and Control of Coal Mill - NTNU

2013/11/20 Coal mill is an important component of the thermal power pla nt. It is used to grind and dry the moisturized raw coal and transport the pulverized coal ± air mixture to the boiler. Poor dynamic performance of coal mill will lead to decrease in the overall efficiency of the power plant, slow load take up rate and fr equent shut down.

获取价格

Rolling Bearings in Air Separators of Vertical Grinding Mills

2019/5/24 in 1958 by the German manufacturer Pfeiffer for crushing and pulverising cement. In early 1960, the bowl and roller mills were modified by Babcock. The air separators of the mills have to meet high requirements with regard to process technology and operational safety. To date, the dynamic air separators (type SLS) were driven via a pinion gear.

获取价格