أرسل لنا رسالة

process layout of roller grinding mill

Roller Mill - Springer

2023/7/4 The basic structure of the roller mill includes the grinding roller, the grinding body, the force generation and transmission mechanism, airflow, and the device for easy replacement. It can be divided into vertical roller mill, horizontal cylin

获取价格

PROCESS OPTIMISATION FOR LOESCHE GRINDING

2017/8/12 The “Stand Alone” real-time optimisation solution for process-optimised operation of Loesche grinding systems with the main focus on efficient performance,

获取价格

Grinding process within vertical roller mills: experiment and ...

2009/1/1 Abstract. Based on screening analysis, laser size analysis, grindability and rigidity tests of samples collected on line from a cement and a power plant, a simulation of the

获取价格

vertical roller Mill design principles and wearing parts repair ...

2014/10/16 Process. Vertical mill conditioning tower and filter based on location, there are two different layout scheme, namely three fan system and dual fan systems. Product collected

获取价格

Optimization of working parameters of high-pressure roller mill

4 之 Figure 4 shows a schematic diagram of the force on the pressure rollers of a high-pressure roller mill, The shaded area is the influence area of the working pressure, in the

获取价格

Loesche vertical roller mills for the comminution of ores and minerals ...

2001/10/1 LOESCHE vertical roller mills are widely used for the comminution of raw materials in the cement industry, for the comminution of clinker and blast furnace slag and for

获取价格

Roller mills: Precisely reducing particle size with greater

2020/11/11 This article introduces roller mills and explains how they efficiently grind friable materials to a uniform final particle size while using relatively little energy

获取价格

Selected Aspects of Modelling and Design

2021/3/1 The essence of the milling process in the roller mills consists of a mutual interaction of mechanical forces exerted on two surfaces, where one of them rolls on the other one, and between them there is the milled and

获取价格

Grinding process optimization - IEEE Xplore

2017/6/19 The modular design of the vertical roller mill comprising 4 to 6 grinding rollers allows the continuation of mill operation even if one roller module is not available. The same

获取价格

Design Considerations for the Construction and

2013/7/9 Sometimes smaller mills (which are part of a larger process) are constructed using only steel. The major elements of the milling process are discussed as follows: The break system is primarily comprised of roller mills.

获取价格

An investigation of performance characteristics

2020/8/12 As one of the three major forces of coal mills, the grinding force exerts a significant impact on the working process of coal mills and parameters like mill current and outlet temperature.

获取价格

process layout of roller grinding mill - Sabo Mining

2023/9/3 process layout of roller grinding mill; Mineral processing milling. WebThe process can be wet or dry but is more commonly carried out wet. Maximum rod length is about 6 to 7 metres, otherwise there is a risk of the rods bowing. The drum diameter is limited to 0.6 or 0.7 times the length of the mill. Characteristics Rod mills are used for ...

获取价格

process layout of roller grinding mill - Sabo Mining

2023/9/3 process layout of roller grinding mill; Mineral processing milling. WebThe process can be wet or dry but is more commonly carried out wet. Maximum rod length is about 6 to 7 metres, otherwise there is a risk of the rods bowing. The drum diameter is limited to 0.6 or 0.7 times the length of the mill. Characteristics Rod mills are used for ...

获取价格

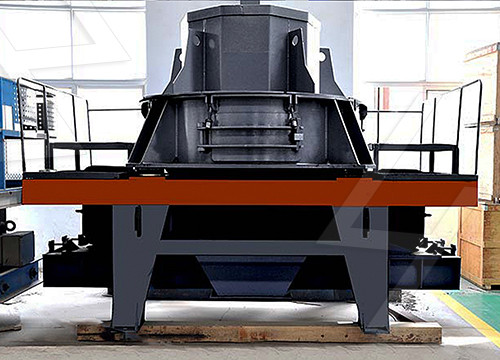

process layout of roller grinding mill - MC Machinery

Process Layout Of Roller Grinding Mill EXODUS . In the crushing process the raw materials firstly sent into the jaw crusher for the primary crushing if necessary the crushed materials will enter in the impact crusher or cone crusher for further crushing then the minerals enter into the ball mill or grinding mill to be grinded next is the ...

获取价格

layout of mining company mill processes – Grinding Mill China

2021/7/14 Design, Metallurgical, Mill, Process, Jobs 4 Mining Ltd, Lower Mill » Free online chat! cement plant layout coal mill – Raymond grinding mill. Precise Process Perfect Products Gulin Mining Equipment Co.,Ltd. Raymond mill,Vertical roller mill,Ball mill » Free online chat! design

获取价格

Rolling of Billets, Types of Mill and General Layout

2024/11/5 Fig. 5.6 Layout of Continuous Billet Mill (With Group Drive). The most widely used layout of a continuous billet mill with group drive, which was used until recently is shown in Fig. 7.4. The mill comprises of two groups of six stands. Each stand arranged consecutively in line with the delivery roll table of the bloom shear.

获取价格

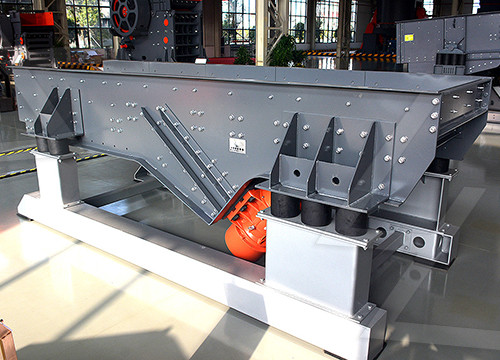

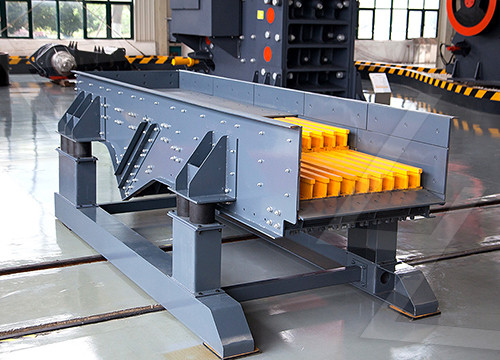

The layout of the dust measuring station: 1-hammer mill, 2-roller mill ...

The layout of the dust measuring station: 1-hammer mill, 2-roller mill, 3-DustTrak II dust monitor, 4-inlet of the raw material prior to grinding, 5-outlet of the raw material after

获取价格

process layout of cement wikipedia - Grinding Mill China

2013/4/17 » rock grinder rental in southern ca; Hot Products Used for process layout of cement wikipedia pew jaw crusher lm vertical mill mobile crusher belt conveyor scm ultrafine mill pfw impact crusher. Popular materials processing machines

获取价格

Grinding and classification performance evaluation and

In this respect, grinding technologies such as vertical roller mills, high pressure grinding roll crushers (HPGR) and the Horomill are used in finish grinding of cement in cement plants in the recent years as they are known to be energy efficient systems. Grinding is achieved by high compression in these systems.

获取价格

The layout of the coal mill with a rotary classifier.

Download scientific diagram The layout of the coal mill with a rotary classifier. from publication: An investigation of performance characteristics and energetic efficiency of vertical roller ...

获取价格

Session 11 - Optimisation of Roller Press System

2024/3/16 This document discusses roller presses, which are compaction tools used primarily as pre-grinders in cement production to increase grinding capacity. Key points: - Roller presses apply high pressure to compact and

获取价格

Reprint from ZKG 3 - Gebr. Pfeiffer

2016/12/19 These are, on the one hand, vertical roller mills (VRM) that have achieved a share of almost 90 % and, on the other hand, ball mills whose share de - creased to just over 1 0 %. Gebr. Pfeiffer SE supplies stand-alone MPS coal grinding mills as well as complete coal grind - ing-drying systems. Both mill and grinding sys-

获取价格

Slag Vertical Roller Mill - m.sbmchina

2023/1/10 3. High grinding efficiency, good quality of finished products. The material stays in the vertical roller mill for a short time, reducing repeated grinding and facilitating the stability of product quality; At the same time, the grinding roller and the grinding plate are not in direct contact, and the iron content in the product is low.

获取价格

The Revolution of Vertical Roller Mills in the Industry

2023/10/7 The vertical roller mill powder grinding system features a simple process flow with minimal equipment, including only the cement vertical roller mill, primary bag dust collector, and main exhaust fan.

获取价格

Horizontal roller mill (Horomill®) application versus hybrid HPGR/ball ...

2009/12/1 Comparisons of Horomill ® and ball mill feed and discharge size distributions are presented in Fig. 4, Fig. 5. Mill feed size distributions of both grinding systems were recorded to be the same in the size range of −25 to +3.35 mm (Fig. 4).Depending on the differences both in operational characteristics and discharge mechanism of the two grinding systems, particles

获取价格

sample layout design in manufacturing process – Grinding Mill

2021/7/14 How to Design a Process Layout eHow. Planning and organization is central to efficient manufacturing.When creating a new manufacturing business or expanding an old one, you should have a design layout » Free online chat! Lean Manufacturing Layout Options – On-Line Training to Improve . Lean Manufacturing Layout Options Process flow

获取价格

Mill Process PDF Mill (Grinding) Gases

2012/11/6 mill process - Free download as (.rtf), PDF File (.pdf), Text File (.txt) or read online for free. This document provides guidelines for process control of vertical roller mills used for limestone grinding. It discusses key performance indexes that are controlled, including mill feeding rate, product fineness, moisture content, specific power consumption, and mill control

获取价格

vertical roller Mill design principles and wearing parts repair ...

2014/10/16 Process Vertical mill conditioning tower and filter based on location, there are two different layout scheme, ... these forces are acting on the vertical mill grinding roller compacted area effectively. Once with a gap, will impact collision between the body and the ...

获取价格