أرسل لنا رسالة

crushing grinding of rock

Effect of the textural properties of rocks on their crushing

2006/10/1 The relations between the textural properties and the physical and mechanical features of rocks were determined. Key words: rock; textural properties; crushing; grinding 1. Introduction Rocks are complex and heterogeneous materials.

获取价格

(PDF) SIZE REDUCTION BY CRUSHING

2017/3/4 Crushing is the first step of mineral processing where the ore/rocks from the mine site is fed into the mechanical equipment in order to

获取价格

Energy considerations in compressive and impact crushing of rock

2008/8/1 The rock from the crushing plant needs to be reduced typically from the range 1–10 mm down to 0.05–0.1 mm in order for the flotation to work efficiently. For this size

获取价格

Understanding the impact of geotechnical ore properties and blast ...

2021/8/15 This ROM fragmentation feeds the JKSimMet crushing and grinding models to predict mill throughput and the product size distribution. This study demonstrates the

获取价格

Reduction of Fragment Size from Mining to Mineral

2022/10/4 The effects of rock fragmentation on the whole size reduction chain from mining to mineral processing are described. The main factors influencing rock fragmentation by

获取价格

A Process for Reducing Rocks and Concentrating Heavy

2016/3/25 mineral constituents of geologic samples, the rock should first be evaluated for tenacity. Tenacity is defined as resistance to breaking, crushing, or bending (Nelson, 2013).

获取价格

Primary Crushing - SpringerLink

Primary crushing brings run-of-mine ore down to a maximum size of the order 4″ to 6″ in average diameter; secondary crushing receives feed at −6″ and reduces it to below “Dry” crushing

获取价格

岩石钻孔爆破粉碎区计算模型的改进 - cstam.cn

2013/5/3 On this basis, the formula for the crushed zone radius in drilling blasting is derived by elastic-plastic mechanics theory. The analysis shows that the size of the crushed zone ranges from 1.2 to 5.0 times of the blasthole

获取价格

Crushing and grinding - (Mineralogy) - Fiveable

Crushing and grinding are mechanical processes used to reduce the size of materials, typically in the mining and mineral processing industries. These processes help liberate valuable minerals

获取价格

Pre-treatment of rocks prior to comminution - ScienceDirect

2017/3/1 Crushing and grinding marginally differ from the fact that crushing liberates particles in coarser size ranges whereas grinding in finer size ranges. Grinding is deemed as

获取价格

The Complete Guide to Primary Crushing,

2023/2/28 Primary crushing is different from other comminution processes, such as grinding, in that it breaks down the material using mechanical force, rather than by using friction or impact. Unlike grinding, which produces a fine

获取价格

Enhancement of taconite crushing and grinding through primary blasting ...

1997/4/1 Sci. 34:3-4, Paper No. 226 ENHANCEMENT OF TACONITE CRUSHING AND GRINDING THROUGH PRIMARY BLASTING Kai Nielsen1; C. Mick Lownds2 1 Department of Geology and Mineral Resources Engineering Norwegian University of Science and Technology, N-7034 Trondheim, Norway 2 Viking Explosives Supply Inc. 12955 Courthouse Blvd.,

获取价格

Use of drilling performance to improve rock-breakage

2020/3/1 In a hard-rock mine, blasting is an important rock-breakage process that impacts energy consumption both in downstream comminution processes and mine productivity. Optimizing the blast fragmentation to improve rock-breakage efficiencies during crushing and grinding is key to mine-to-mill (MTM) optimization.

获取价格

(PDF) Overview of Mineral Processing Methods - ResearchGate

2015/8/3 Size reduction typically involved crushing, grinding, and screening (Balasubramanian, 2015) and various separation techniques were employed dependant on the mineral of interest. ...

获取价格

(PDF) Reduction of Fragment Size from Mining to Mineral

2022/10/4 The worldwide mining industry consumes a vast amount of energy in reduction of fragment size from mining to mineral processing with an extremely low-energy efciency, particularly in ore crushing ...

获取价格

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017/3/4 3.3 Crushing of rock and minerals: Crushing is the largest process operation in minerals processing. ... especially during the processes of crushing and grinding mineral ore. Dust has the ...

获取价格

Evaluation of size reduction process for rock aggregates in

2020/6/4 The size reduction process of rocks in cone crushers is one of the most important issues, particularly for the secondary and tertiary stages of crushing operations. In this study, 17 different rock types were considered for the evaluation of their size reduction variations that occurred in a laboratory-scale cone crusher. Based on several mineralogical, physico

获取价格

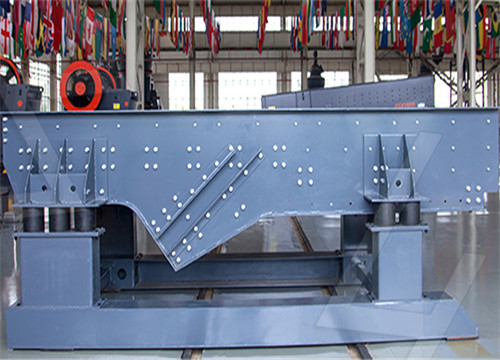

Crushing and Grinding Process - JXSC Machine

2019/10/8 The crushing and grinding operations are an important part of the processing of mineral resources, and it is also operation with high investment and high energy consumption. In the case of metal mines, equipment investment in crushing operations accounts for 65% to 70% of the total plant value, power consumption is about 50% to 65%, and steel consumption is as

获取价格

Understanding the impact of geotechnical ore properties and blast ...

2021/8/15 Mackenzie (1967) carried out one of the earliest studies in the impact of blasting on downstream mining and mineral processing stages, concluding that adequate rock fragmentation improves the productivity of later steps, such as loading, haulage, crushing and grinding. McKee et al. (1995) conducted the earliest research at JKMRC regarding the

获取价格

Minerals Processing Equipment Cone Crushers Yate

2023/10/9 Yate offers an unparalleled level of customization for your diverse applications including crushing, grinding, screening and feeding of raw materials. Reliable Manufacturer of Crushing, Grinding and Screening Equipment ... With more than 20 years of experience within technical rock crushing solutions, we offer you a full line of crushing and ...

获取价格

Evaluation of blast fragmentation effects on jaw crusher

2021/9/21 The fragmentation rate and particle size distribution of the muckpile after blasting have important influences on the performance of subsequent mining activities such as loading, hauling, crushing, grinding, and the overall costs of the mine. Drilling and blasting are important steps in the chain of mining processes, and its results affect the efficiency of

获取价格

Modeling and Improving the Efficiency of

2023/6/30 optimization in the modeling of mineral processing, namely the crushing and grinding processes, has been investigated, and the effectiveness proven [ 26 ]. The automation of any technological ...

获取价格

An experimental work on the crushing and grinding features

2006/1/1 grinding and crushing characteristics of the rocks were investigated, and the relations among them were then analyzed using statistical methods. The relations between the textural properties and ...

获取价格

Types of Rock Crushers Quarry Crushing Equipment Kemper

5 之 Stages of Rock Crushing: Crushing Stations. ... Cone crushers, vertical shaft impactors (VSIs), horizontal impact crushers, or even high-pressure grinding roll crushers may be used in the final reduction position. Types of Rock Determine the Crushers You Need. Sandstone, limestone, gravel, and granite are arguably the most common aggregates ...

获取价格

(PDF) Rock Fragmentation by Blasting – a review

2016/9/1 Predicting the mean fragment size (50% passing size) in rock blasting is a critical component of mining operations because it directly affects downstream processes such as loading, hauling, and ...

获取价格

Mechanistic Study of a Microwave Field-Controlled

2022/8/12 controlled static crushing agent rock-breaking method. The study reached the following main conclusions: (1) microwave heating is better than conventional ... by grinding inorganic compounds with high-temperature-calcined CaO as the main component and corresponding additives such as cement, which is noncombustible, non-

获取价格

Hill Country Rock Milling - Rock Crushing - FAIR OAKS, Texas

Serving the Texas Hill Country *Veteran Owned and Operated* (830) 282-1828

获取价格

(PDF) New testing methodology for the quantification of rock ...

2018/11/1 Crushing is a size reduction process that plays a key role in both mineral processing and crushing–screening plant design. Investigations on rock crushability have become an important issue in ...

获取价格

岩石钻孔爆破粉碎区计算模型的改进 - cstam.cn

2013/5/3 为了研究炮孔周围岩石的破坏机理,准确预测粉碎区的范围,提出了一种计算钻孔爆破粉碎区范围的改进模型。该四分区模型考虑了破裂区内侧的环向压应力和炮孔空腔膨胀的影响,假定粉碎区为丧失了内聚力但仍具有内摩擦力的散体介质。

获取价格

Mineral processing Metallurgy, Crushing Grinding

Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue. It is the first process that most ores undergo after mining in order to provide a more concentrated

获取价格