أرسل لنا رسالة

Impact crushing and coarse powder grinding

Scwn-C400 Ultra-Fine Powder Impact Mill Grinding Machine

2024/10/8 It is widely used in the ultrafine grinding, disagglomeration, and particle shaping of various dry powder materials in industries such as non-metallic mining, chemicals, building materials, food, medicine, pesticides, feed, new materials, and environmental protection,

获取价格

Grinding - Hosokawa Alpine

Pre-crusher are used for coarse crushing and break up coarse materials to a particle size of <30 mm. Crushing is achieved using counter rotating grinding rollers that are equipped with either bars or discs.

获取价格

Impact of HPGR operational pressing force and material

2024/9/1 HPGR-based crushing technology, since its first industrial implementation in the mid ’80s, has found applications in over 1000 plants, starting from cement clinker grinding

获取价格

Grinding Contribution and Quantitative Separation of Impact

2023/8/3 In this study, grinding contribution and quantitative separation of impact and grinding mechanism in cylindrical mill were creatively researched, and the grinding technical

获取价格

Milling Studies in an Impact Crusher I: Kinetics Modelling

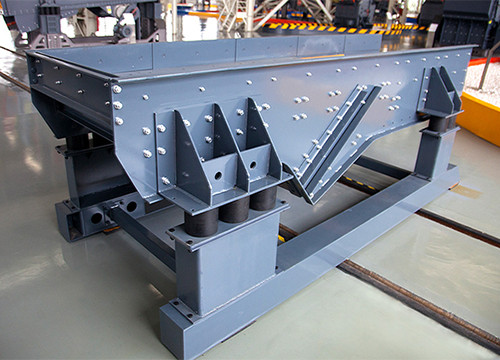

Types of Crushers: Choosing the Right One for

2024/7/17 Coarse crushing: Use jaw crushers, gyratory crushers and hammer crushers in primary crushing to break large materials into medium sizes. Medium crushing: Employ cone crushers or impact crushers in secondary

获取价格

Understanding the impact of geotechnical ore properties and blast ...

2021/8/15 Therefore, blast design and geotechnical ore properties have a significant impact on downstream processes such as crushing and grinding. This work aims to

获取价格

Study on the Population Balance Dynamics

2024/6/24 Based on the JK drop weight test data of quartz and pyrrhotite and the research results of their impact crushing characteristic parameters, this paper calculates the specific crushing energy (E cs) of mineral samples

获取价格

Basics of Size Reduction-Coarse to Medium Grinding

Crushing is the act of pressing tightly on the top and bottom, or both sides, of a material so that its size is reduced. The most commonly used crushers for size reduction are jaw crushers, cone

获取价格

Phase separation of recycled concrete powder during grinding

2023/9/1 During the grinding process, minerals with low elastic modulus (portlandite, C–S–H gel, as well as calcite) were easier to grind into fine particles than high elastic modulus

获取价格

Utilization potential of aerated concrete block powder and

2020/3/30 Apart from that, it can also be seen from Fig. 15 (a) that the recycling efficiency of ACBs fine powder (<0.045 mm) is higher, which indicates that although the energy consumption of crushing and grinding ACBs into fine powder is high, the R e is still higher than that of the medium and coarse powder. In other words, after balancing the energy ...

获取价格

Bsc Coarse Crusher - Chilli Flakes Making Machine and Root Grinding

4 之 Grinding and Impact. Cutter Material. High-Speed Steel. Finished Surface. ... Our BSC Coarse Crusher is used as specialized equipment for coarse crushing hard and tough materials like plastics, rubber, etc. Especilally, it is not limited by viscosity, hardness, softness and fiber shape of material and has good effect to all materials ...

获取价格

Grinding for food powder production - ScienceDirect

2024/1/1 Compression or crushing is used particularly in the food industry where roller mills, smooth or ribbed, are commonly found. The impact mills will achieve different orders of magnitude in terms of sizes, from coarse grinding with hammer mills to ultra-fine grinding with mill jets of air via the fine grinding with pin mills.

获取价格

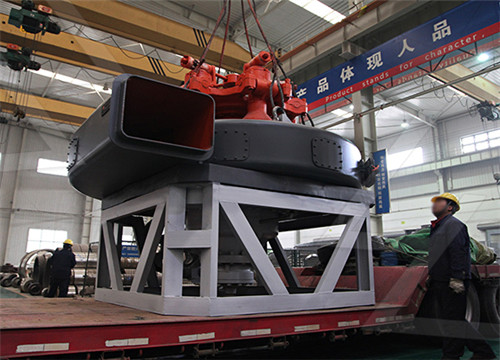

How to Process Dolomite: Dolomite Crushing And Grinding

2023/1/13 Jaw crusher (coarse crushing), cone crusher (secondary crushing), vertical shaft impact crusher (fine crushing and sand making), which can form a three-stage crushing and sand making plant. ... mainly including European coarse grinding mill for producing 6-40mesh dolomite powder, fine grinding mill (LM vertical roller mill, MTW European ...

获取价格

MACHINES FOR COARSE GRINDING CRUSHING - Engisol

COARSE GRINDING CRUSHING REKORD IMPACT MILLS ... TANK BASED MIXING SYSTEMS MATERIAL HANDLING IBC Powder handling ROBOTIC POWDER HANDLING PACKAGING TECH PACKAGING LINES ... agglomerates and lump breaking enabling pneumatic transport and coarse crushing of brittle feed products are the main applications for the

获取价格

Shale Crushing And Grinding Machines - sbmmill

2024/5/22 Shale Crushing and Grinding Process Workflow. Primary Crushing: Large shale rocks are fed into jaw or hammer crushers for initial size reduction. Secondary Crushing: Cone or impact crushers further reduce the size of the material. Screening and Classification: Crushed shale is screened to separate it into different-size fractions. Grinding: The screened shale is

获取价格

(PDF) Effects of Crushing and Grinding on the Porosity of

2023/9/13 The objective of this paper was to study the impact of crushing and grinding on the porosity of hardened cement paste, which is responsible for the high values of recycled concrete aggregate (RCA ...

获取价格

Dry Fish Powder Grinding Machine, Fish Grinder Pulverizer

2024/9/20 Dry fish powder grinding machine adopts hammer crusher, which relies on the impact of high-speed rotating hammers to grind the coarse fish meal into fine particles and discharge them through a screen. +86 13812119520 ... The dry fish material enters the crushing chamber through the material door and the screw conveyor, and is sheared and ...

获取价格

Impact crushing of concrete for liberation and recycling

1999/11/1 The gravel, split gravel or sand material (d=2–16 mm), with a total mass fraction of about 60% in concrete (e.g., DIN 1045, 3rd aggregate grading curve [2]) is to be liberated by impact comminution (Fig. 1).The liberation grade, index LG, of a fraction i is defined as the mass content of liberated particles μ LG,0,i or μ LG,0–50,i.Generally, in the context of building

获取价格

Understanding the impact of geotechnical ore properties and blast ...

2021/8/15 Mackenzie (1967) carried out one of the earliest studies in the impact of blasting on downstream mining and mineral processing stages, concluding that adequate rock fragmentation improves the productivity of later steps, such as loading, haulage, crushing and grinding. McKee et al. (1995) conducted the earliest research at JKMRC regarding the

获取价格

100 Mesh Cocoa Powder Grinding Machine for

2024/9/26 The cocoa powder grinding machine has good crushing effect, and the fineness of cocoa powder can reach 100 meshes. ... so it is necessary to use the crushing equipment for coarse crushing, and then use the machine for

获取价格

Products-Industrial Grinding Mill, Ultrafine

Grinding Mill mofen. Industry Technology Group, Shanghai Ultrafine Powder Tech. Co., Ltd. has ultra-fine grinding mill, ultra-fine vertical mill, Raymond mill, coarse mill. The product processing range covers 0-3mm

获取价格

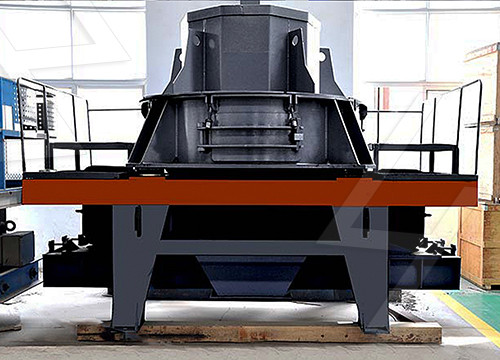

Types of Crushers: Choosing the Right One for Each Stage

2024/7/17 The compound crusher, a double-rotor primary impact crusher, is a new type of fine crushing and coarse grinding product launched by FTM Machinery. Materials entering the high-speed rotating impeller are centrifugally thrown outward, colliding with other materials, then repeatedly colliding and grinding between the impeller and casing before ...

获取价格

A study on the correlation between fractal dimension and

2024/11/1 Understanding the mechanical properties of ores is critical for optimizing the crushing and grinding processes. To investigate the breakage characteristics of tungsten ores with different particle sizes in different crushing sections during the comminution process, the breakage index (t 10) and fractal dimension (D) of different particle sizes in different crushing

获取价格

Impact crushing of waste concrete for coarse aggregate

2024/3/1 Impact crushing of waste concrete for coarse aggregate liberation by water jet. Author links open overlay panel Zefeng ... Improvement of recycled aggregate properties through a combined method of mechanical grinding and microbial-induced carbonate precipitation. Constr. Build. ... Powder Technology, Volume 438, 2024, Article 119571. Chunlin Su ...

获取价格

Grinding (Comminution) - an overview ScienceDirect Topics

The grains are decreased in size by a mix of impact and abrasion, utilizing different pulverizing mills (Fig. 9.1 right). ... Coarse particles of hard minerals in the coal, such as quartz, can also give rise to abrasion of the grinding equipment or of exposed surfaces in the combustion path. ... crushing, grinding, and pulverizing in the ...

获取价格

Utilizing Impact Crushers in Algeria: Advantages and

2024/5/6 Investing in impact crushers provides a cost-effective solution for Algerian industries seeking to optimize their crushing operations. These machines offer a balance of performance and affordability, allowing businesses to achieve high productivity while minimizing operational costs over the long term. 5.Reduced Environmental Impact:

获取价格

Modeling fines in blast fragmentation and its impact on crushing

1999/1/1 Comparison of the accumulated cost of: powder, selected wear materials and electricity; indicate a strong, inverse correlation with powder factor (lbs powder/long ton of rock).

获取价格

How to choose a limestone grinding mill - SANDMINE

2024/1/18 For ultrafine powder processing, ring roller micro-powder mills and ultrafine vertical mills can be chosen. For coarse powder processing, coarse powder mills can be selected. Classification: The milled material is classified by a powder separator, and the unqualified powder particles are returned to the main machine for re-milling.

获取价格