أرسل لنا رسالة

coal mill gear box oil temperature requirement

Extended Abstract (Control ID 2617231) - Society of

2017/1/31 over a period of 2500 hours in a coal mill gear box in back to back manner. Results Discussions: EIGO and CIGO meets physico-chemical requirements as per DIN 51517 (CLP) Part 3 specification. EIGO exhibits much superior oxidation resistance to oxidation as

获取价格

How to Save a Gearbox Running Hot At 170°C

2024/11/13 To resolve the dryness of the gearbox, I topped-up 13 L of the relevant gear oil Castrol Opti BM 220 and checked the temperature. Temperature reached 140°C immediately. Added 13 L of gear oil plus 20 L of detergent

获取价格

Coal mill - pulveriser lube oil - CJC

For coal mill pulveriser lube oil the following CJC ® system solutions apply: Coal Mill Filter 1, HDU 27/81; Oil Contamination Monitor, OCM15; The CJC ® System solutions fit all coal mill

获取价格

How Temperature Can Affect Your Industrial Gearbox - Amarillo Gear

2018/5/4 Getting temperature readings and oil samples can help to determine whether a thorough examination of the gearbox is needed. Sometimes, a minor adjustment can prevent

获取价格

Industrial Gearboxes - NGC Transmission

2024/2/13 industry, coal and limestone mill in power plants A center drive gearbox is driving tube mills from the end sur-face. Large gearboxes are needed at a lower rated power

获取价格

PROCESS OPTIMISATION FOR LOESCHE GRINDING

2017/8/12 Loesche optimization tool for grinding plant. The LMmaster is a system designed by Loesche to optimize grinding plants from the start of the material feed onwards. The

获取价格

Analysis of Oil Film Temperature Distribution of the High

2005/1/1 Analysis of Oil Film Temperature Distribution of the High Speed Shaft Journal Bearings of Gear Box Applied in the Coal Mine Hoisting Machine. January 2005. DOI:...

获取价格

LOESCHE-MILLS

2017/8/12 The specially-developed hydraulic roller relief system enab-les grinding of different fuels (both hard and soft) and impro-ves the machine control response. Individual

获取价格

Lubrication Checkup: Gearbox Overheating -

2013/12/19 An oil-temperature rise reacts according to the Arrhenius rule—a temperature- change-dependent failure-rate rule—that states for every 18 degrees F (10 degrees C) increase in temperature of the oil, the lubricant life

获取价格

Informed Gear Oil Selection Can Help Reduce

2 之 Four temperature sensors were installed and monitored on the gearbox, two of them of major importance: oil sump temperature and water-cooled input shaft-bearing temperature. With respect to oil sump

获取价格

B2B Intl Service - BALL MILL/COAL MILL OVERHAUL

I. GEARBOX. 1. Position - Position of gearbox in ball mill/coal mill system 2. Common problems: + Gearbox dirt, vibration and temperature do not meet standard quality due to long-time operation in harsh environments. + Gears and bearings are misaligned and broken. + Gear contact is misaligned. + Axial concentricity is deflected.

获取价格

gear box for 85e coal mill - tablesandthyme.co

Coal Mill Gear Box Oil Temperature Requirement-powder ... Gearbox Of Coal Mill Hadoop Training Chennai. Gear box for coal mill gearbox of e coal mill germany two stage gearbox for a coal mill grinder two stage gearbox for a coal mill grinder xsm excellent mining crushing machinery products or production line design the company is committed to building the

获取价格

Derivation and validation of a coal mill model for control

2012/5/1 Coal fired power plants are heavily used due to large and long lasting coal resources compared with oil or natural gas. An important bottleneck in the operation of this particular kind of plants, however, is the coal pulverization process, which gives rise to slow take-up rates and frequent plant shut-downs (Rees Fan, 2003).In typical coal fired power plants,

获取价格

Coal mill gearbox case study verF 2 - PSR Proactive

2017/12/25 The Problem - Coal fired power plants typically operate several ball mills or coal pulverizing mills to crush the incoming coal to the optimum size for combustion. This means that each power generation unit has five or six mills. The gearboxes that run these coal mills are usually lubricated with high viscosity oil, such as ISO VG320 or ISO VG460.

获取价格

Coal mill - pulveriser lube oil - CJC

Maintain lube oil on coal mill pulveriser clean and dry, you avoid shut-downs, reduce high costs for spare parts and reduce the risk of unplanned breakdowns. Language. ... Coal Fired Power Plant_Mill Driven Gearbox_Gear Oil_Millmerran Australia_ASIN5144 Coal Mill Gear_Babcock MPS 190 Rolling_Gear Oil_Elsam-Studstrup_ASIN5051 ...

获取价格

Gearbox Oil Guide: Everything You Need to Know - Houston Pump and Gear

2023/12/22 Learn about gearbox oil types, viscosity charts, selecting right oil, and best practices for gearbox efficiency and issue prevention. ... The viscosity index tells you how well a fluid can protect its viscosity during changes in temperature. Gear oil viscosity is crucial because it affects lubrication, load-carrying capacity, temperature ...

获取价格

Coal mill gear box lubrication cooling cleaning method

A technology for lubricating and cooling coal mills, used in gear lubrication/cooling, engine lubrication, and lubricating parts, etc., can solve the problems of low degree of automation control, high investment cost, large space occupation, etc., and achieve small space occupation. , less investment, enhanced protection effect

获取价格

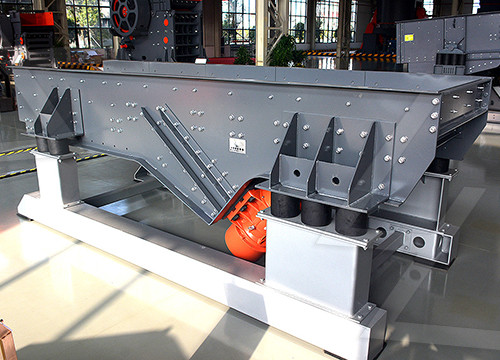

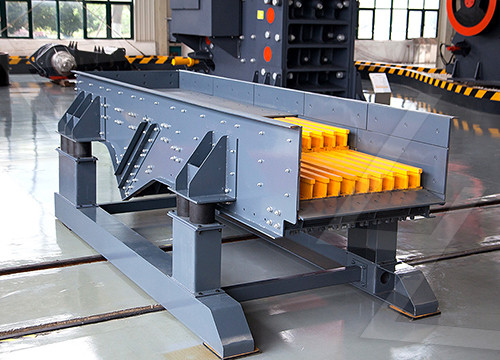

Coal mill gearbox - DPTK - dpkt.vn

Coal mill gearbox; Coal mill gearbox ... It can be provided splash lubrication and forced lubrication for all gears and bearings according to the requirement to ensure the safe operation of the gearbox. 5. Good sealing technique ensures no leakage of lubricating oil. Related products. Explosion-proof Tank Inspection Vessel Light – BAK85 ...

获取价格

Review of control and fault diagnosis methods applied to coal mills

2015/8/1 Mill problems originate mainly due to poor controls or faults occurring within the milling system. As discussed by G.Q. Fan and N.W. Rees [3], the control of mills remains very simple in most of the power plants due to the fact that the mill system is highly nonlinear with strong coupling among the variables and it is very difficult to measure some important

获取价格

An investigation of performance characteristics and

2020/8/12 As one of the three major forces of coal mills, the grinding force exerts a significant impact on the working process of coal mills and parameters like mill current and outlet temperature.

获取价格

Coal mill gearbox - cn-donly

Coal mill gearbox. Features. ... It can be provided the splash lubrication and forced lubrication for all gears and bearings according to the requirement to ensure the safe operation of gearbox 5. Good sealing technique ensure no

获取价格

Ultra-Supercritical Coal Fired Power Plant Coal

Table 1 details potential life extension of components as fluid cleanliness is improved. A review of how ISO codes are determined as provided. Step 3 – Install Hy-Pro high efficiency glass media or desiccant breathers on all

获取价格

E Mill Gear Box For Coal Grinding In Power

Elecon have fabricated and supplied 8.5E 10 Mill Gear box for Coal Grinding in Power Plants. This have been developed against the existing imported unit for easy replacement without disturbing position of Motor and Coal Mill. and these

获取价格

Extending Gear Life in a Coal Pulverizer Gearbox - Power Engineering

2007/8/1 After consulting with the lubricant supplier, all parties determined that AGMA 7 RO (rust-and-oxidation inhibited) (ISO 460) synthetic gear oil would best protect the gearbox in this application.

获取价格

Gearbox Filtration - Industry Applications

4 之 Coal Mill Gearbox Filtration. Break the drain and refill gearbox oil change cycle and improve reliability, extend useful oil life and avoid premature contamination gearbox rebuilds by installing Hy-Pro FSL dedicated off-line filter skids specifically designed for high viscosity lube oils. High flow LF housings are also a good fit for adding high efficiency filtration to existing re

获取价格

Optimisation of coal fineness in pulverised-fuel boilers

2017/11/15 The analysis of the impact of the composition of the mineral part of the Polish hard coal to the abrasion of mills was made. Based on the measurements carried out and the actual periods between overhauls of mills, which were determined during the operation, a correlation was found to determine the abrasive wear rate of the elements of ring-ball mills

获取价格

MAAG® GEAR WPU Gear Unit MAAG Gear

Reliably drive vertical roller mills with our fit-for-duty gear unit. The two series of our MAAG® GEAR WPU Gear Unit ensure that your vertical roller mill has the dependable drive system you need, whatever your required power range. With specifications to ensure safe operation in coal mills, our two-stage gearbox has you covered.

获取价格

Ball Mill Gear Box Lubrication CIRCOR - circorpt

Coal plants use a mill machine to finely pulverize coal before burning. These mills use large speed reducers between the motor drive and the mill and pumped or forced oil lubrication systems lubricate this equipment. Lubrication pump(s) may be driven from the reduction gear box or separately driven using electric motors. Three screw pumps are ...

获取价格

Pulverizer Plant OM Aspects - eecpowerindia

2013/12/6 Nomenclature-Bowl Mills 583 XRS / 803 XRP Bowl mills 58,80 stands for bowl diameter in inches If the number is even then its shallow bowl mill. If the number is odd then its deep bowl mill 3 - number of rollers three nos. X - frequency of power supply 50 cycles.In USA ’x’ means 60 cycles. R- Raymond, name of the inventor

获取价格