أرسل لنا رسالة

gypsum production ball

Effect of Ball Milling Time on the Performance of

2022/1/11 The use of phosphogypsum to prepare phosphorus building gypsum (PBG) is of great value to the resource utilization of phosphogypsum. In this study, PBG was ball-milled to

获取价格

Highly efficient modified phosphogypsum building gypsum

2024/4/12 Ball-milling for 2 min and 5 min showed different microstructures indicating conversion of gypsum dihydrate to hemihydrate gypsum and anhydrite gypsum with varying

获取价格

Strength Prediction of Ball-Milling-Modified Phosphorus Building Gypsum ...

2022/11/11 In this paper, the absolute dry flexural strength and the absolute dry compressive strength of phosphorus building gypsum were compared under different mass

获取价格

An experimental study on the ultra-fine grinding of gypsum

2016/4/1 In this study, batch grinding tests of gypsum ore were performed using a ball mill to investigate the effects of grinding parameters such as mill speed, ball filling ratio, ball size

获取价格

11.16 Gypsum Manufacturing - US EPA

2015/9/10 A flow diagram for a typical gypsum process producing both crude and finished gypsum products is shown in Figure 11.16-1. In this process gypsum is crushed, dried,

获取价格

Strength Prediction of Ball-Milling-Modified Phosphorus Building Gypsum ...

2022/11/11 In this paper, the absolute dry flexural strength and the absolute dry compressive strength of phosphorus building gypsum were compared under different mass

获取价格

Enhancing the recovery of gypsum in limestone-based wet

2017/7/1 The most common system for flue gas desulfurization (FGD) is the wet scrubbing process in which, the contact between the flue gases to be treated and an alkaline sorbent

获取价格

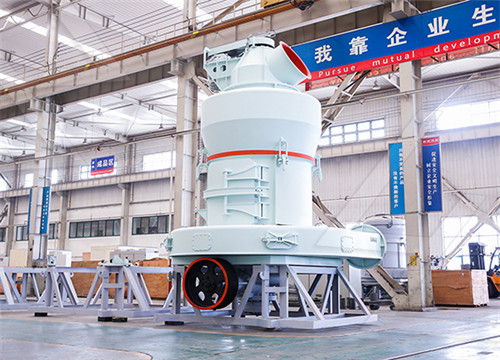

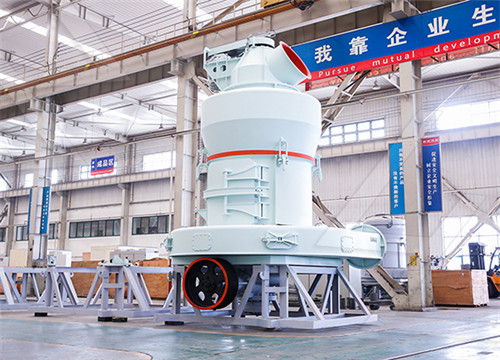

Enhancing efficiency in gypsum powder production with ball

2024/10/13 Gypsum powder production is a crucial industry that requires precision and efficiency. One of the key components in this production process is the ball mill. Ball mills are

获取价格

Ultrafine Powder Dry Mill Ball Mill Phosphate Gypsum Production

2024/10/23 Ultrafine Powder Dry Mill Ball Mill Phosphate Gypsum Production line Ball mill is an efficient tool for grinding various kinds of materials into fine powder. They are generally

获取价格

sbm/sbm gypsum mini ball mill use in grinding ball mill production

Write better code with AI Code review. Manage code changes

获取价格

Enhancing the recovery of gypsum in limestone-based wet

2017/7/1 The so obtained values of gypsum specific production were in line with Tognotti (2007) that, with reference to the ENEL power plant of La Spezia (Italy), fed with coal and characterized by an hourly capacity of 2,370,000 Nm 3 /h of flue gas, a yearly mass flow of removed SO 2 of 29,364.3 t SO 2 removed/year and a yearly gypsum production of ...

获取价格

Enhancing efficiency in gypsum powder production with ball

2024/10/13 Gypsum powder production is a crucial industry that requires precision and efficiency. One of the key components in this production process is the ball mill. Ball mills are commonly used in gypsum powder production lines for the grinding and mixing of materials. The Role of Ball Mills in Gypsum Powder Production: Ball mills are extensively used ...

获取价格

High precision gypsum block production line, prefabricated

Shandong Dalu New Material Environmental Protection Technology Co., Ltd. have fully implemented the ISO9001 quality standard system certification and can customize various specifications of high-precision gypsum block production lines, prefabricated wall panel production lines, and composite insulation block production lines according to customer needs.

获取价格

Agricultural Gypsum Market Size, Forecast Growth Report

The “Global Agricultural Gypsum Market” study report will provide a valuable insight with an emphasis on the global market including some of the major players such as BNBM, Saint-Gobain, Etex Corp, Knauf, USG, National Gypsum, Boral, Yoshino, Baier, Jason. Agricultural Gypsum Market Segmentation

获取价格

How To Set Up a Gypsum Powder Production Line From

2023/11/2 Setting up a gypsum powder production line requires careful planning and a good understanding of the overall process. Gypsum powder is widely used in the construction industry for making drywall, plaster, and other building materials. ... Wide Range of Production Capacities: Ball mills come in different sizes and capacities to suit various ...

获取价格

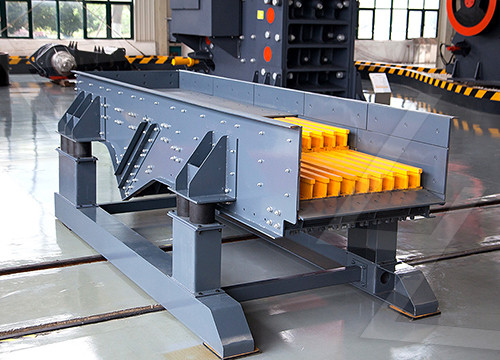

Gypsum Powder Manufacturing Gypsum Powder Making

Gypsum powder-making process. According to the process requirements, the construction gypsum production line is usually divided into five parts, including crushing system, storage conveying system, grinding system, calcining system, and electric control system.. STEP1. crushing system. The size and specifications of gypsum ores are different after mining, and

获取价格

gypsum ball mill - LinkedIn

2021/1/25 Gypsum ball mill is for making gypsum powder. Dry ball mill is the solution for production gypsum powder.

获取价格

(PDF) Effect of Ball Milling Time on the Performance of

2022/1/11 The use of phosphogypsum to prepare phosphorus building gypsum (PBG) is of great value to the resource utilization of phosphogypsum. In this study, PBG was ball-milled to obtain phosphorus ...

获取价格

Efficient stabilization of barium- and gypsum-bearing tailings ...

2023/2/28 Efficient stabilization of barium- and gypsum-bearing tailings by one-step dry ball milling—An ingenious inspiration Separation and Purification Technology ( IF 8.1) Pub Date : 2023-02-25, DOI: 10.1016/j.seppur.2023.123473

获取价格

CN101152737A - Method for squeezing to produce

The key factor that influences gypsum retardation ball ordinary production in step (3) is the free water content that chemical gypsum and semi-hydrated gypsum mixture are selected in modification, this free water content should be lower than 11%, otherwise material viscosity increases, made retardation ball demoulding difficulty influences ...

获取价格

An Important Tool With No Instruction Manual: A Review of Gypsum

2017/1/1 Clearly, gypsum application to soils can have a multitude of impacts on both chemical and physical properties, which can ultimately affect crop production and environmental quality (Table 1).The diversity in chemical and physical impacts is a direct result of several different chemical processes associated with gypsum applications (Table 2). ...

获取价格

Gypsum Disposal Gypsum Grinding Gypsum

2024/8/23 GYPSUM POWDER PRODUCTION LINE Processing capacity: 50,000-300,000 tons/year Processing materials: phosphogypsum, desulfurized gypsum, industrial by-product gypsum ... plate chain elevator and other

获取价格

Strength Prediction of Ball-Milling-Modified Phosphorus Building Gypsum ...

2022/11/11 Phosphogypsum is an industrial byproduct from the wet preparation of phosphoric acid. Phosphorus building gypsum can be obtained from phosphogypsum after high-thermal dehydration. This study aimed to analyze the influence of ball milling with different parameters on the strength of phosphorus building gypsum. In this paper, the absolute dry

获取价格

Strength Prediction of Ball-Milling-Modified Phosphorus ...

2022/11/11 In this paper, the absolute dry flexural strength and the absolute dry compressive strength of phosphorus building gypsum were compared under different mass ratios of material to ball, ball-milling speed, and ball-milling time, and the NSGM (1,4) model was

获取价格

High precision gypsum block production line, prefabricated

Shandong Dalu New Material Environmental Protection Technology Co., Ltd. have fully implemented the ISO9001 quality standard system certification and can customize various specifications of high-precision gypsum block production lines, prefabricated wall panel production lines, and composite insulation block production lines according to customer needs.

获取价格

flowsheet of gypsum production - LinkedIn

2024/9/9 A flowsheet for gypsum production typically involves several stages, starting from the raw material (gypsum ore) to the final product (gypsum boards or plaster). Below is an outline of the basic ...

获取价格

Gypsum and Plaster Board Production Line Limestone Grinding Ball

2024/1/11 Gypsum and Plaster Board Production Line Limestone Grinding Ball Mill Powder Making Grinder Machine, Find Details and Price about Gypsum Powder Making Machine Gypsum Powder Machine from Gypsum and Plaster Board Production Line Limestone Grinding Ball Mill Powder Making Grinder Machine - SHIJIAZHUANG WUXING MECHANICAL CO., LTD.

获取价格

Strength Prediction of Ball-Milling-Modified Phosphorus Building Gypsum ...

2022/11/11 As can be seen from Figure 1, under different mass ratios of material to ball and milling speed, the absolute dry flexural strength of phosphorus building gypsum first increased and then decreased with the increase in milling time.When the mass ratio of material to ball was the same, faster ball milling had a greater influence on the absolute dry flexural

获取价格

Effect of Ball Milling Time on the Performance of

2022/1/11 The production of PBG from phosphogypsum is one of the primary ways to consume phosphogypsum [4, 5]. ... The results showed that the best performance of building gypsum was obtained when the ball milling time was 3 min. However, if milling time continues to increase, the performance of the building gypsum cannot be improved. ...

获取价格