أرسل لنا رسالة

cement mill capacity calculation

The Cement Plant Operations Handbook - International

2019/4/30 The Cement Plant Operations Handbook is a concise, practical guide to cement manufacturing and is the standard reference used by plant operations personnel worldwide.

获取价格

Ball Mill Design/Power Calculation

2015/6/19 Use this online calculators for Motor Sizing and Mill sizing as well as mill capacity determinators. In extracting from Process Machinery Reference Manual I will also provide 2 Ball Mill Sizing (Design)

获取价格

cement plant calculations kiln, mills, quality, combustion, etc.

Most Frequently Used Calculators Now Available Online For Quality Evaluation and Process Control in Cement Industry. Lime Saturation Factor (LSF) Silica Modulus (SM) Alumina

获取价格

CEMENT FORMULAE HANDBOOK - Green Business Centre

2024/6/4 Cement plants are adopting the best manufacturing practices and the latest energy efficient technologies, and the industry deserves credit for growing at a fast pace while

获取价格

Calculations for design of ball mills for cement grinding

2024/10/13 2) Capacity - The second step is to calculate the capacity required by the ball mill. This will involve determining the weight of cement that can be processed per hour and

获取价格

How can I calculate cement ball mill capacity? - WinnerMac

2023/5/24 The capacity of a cement ball mill can be calculated using the formula: C = (k * Q)/ (p * S * G)

获取价格

en/115/cement mill capacity calculation solution for ore

Navigation Menu Toggle navigation. Sign in Product

获取价格

Ball mill calculations, tube mill calculations, separator

All Ball mill or tube mill calculation, Critical speed, Ball Size calculations, Separator efficiency, Mill power cnsumption calculation, production at blain Optimization Online Training

获取价格

sbm/sbm calculation of cement ball mill capacity grinding mill

Contribute to brblmd/sbm development by creating an account on GitHub.

获取价格

Answered: 3. A cement grinding mill "A" with a bartleby

3. A cement grinding mill "A" with a capacity of 50 tons per hour utilizes forged steel grinding balls costing P12,000 per ton, which bave a wear rate of 100 grams per ton cement milled. Another cement mill "B: of the same capacity uses high chrome steel grinding balls costing P50.000 per ton with wear rate of 20 grams per ton cement milled.

获取价格

BUCKET ELEVATOR EXCEL CALCULATION

Dust tight bucket elevators show above distribute grain to silos and storage. The three types of bucket elevator in common use: Centrifugal, Continuous, and High Speed are described in this 1 PDH course. Bucket elevators are used to: lift

获取价格

calculation of cement ball mill capacity - -china

cement ball mill capacity calculation – Grinding Mill China. Posted at: August 16, 2012. ball mill capacity calculation,price of ball mill for talc ball mill capacity calculation.

获取价格

The Cement Plant Operations Handbook - International

2019/4/30 Cement mill specific power consumption – 4. Other systems – 5. De-bottlenecking – ... Storage capacity 15. Cement plant construction and valuation 244 1. New plant construction – 2. ... Cement plant investment costs – 4. Project phases – 5. Plant valuation Section B – Process calculations and miscellaneous data B1. Power 262 1 ...

获取价格

Ball Mill Performance Efficiency Formulas - INFINITY FOR CEMENT EQUIPMENT

Ball Mill Performance Efficiency Formulas. IF YOU WORK IN A CEMENT PLANT AND YOU NEED COURSES AND MANUALS LIKE THIS MANUAL AND BOOKS AND EXCEL SHEETS AND NOTES I SPENT 23 YEARS COLLECTING THEM YOU SHOULD CLICK HERE TO DOWNLOAD THEM NOW ... Target SO3 content in cement, % Sclk: 0.3: Pu: Gypsum purity,

获取价格

Cement Mill Optimization: Practical Strategies for Enhanced

Cement mills are critical components in the cement manufacturing process, responsible for grinding raw materials into fine powder to produce cement. ... software can lead to up to 3% reduction in specific energy consumption and up to 10% increase in production capacity. Optimizing ball mill internals: The internal design of the ball mill ...

获取价格

Cement mill notebook PDF Free Download - SlideShare

2015/1/7 3. ~ Nael Shabana 20103~ 6.0 Ventilation 7.0 Grinding and Generation of Heat 7.1 Heat Generation in Tube Mills 7.2 Cooling Procedures During Finish Grinding 7.3 Heat Balance for Mill Cooling 8.0 Cement Mill Specific Power Consumption 8.1 Calculation of Cement Mill Power Consumption 8.2 Calculation of the Specific Consumption of Energy per Ton of

获取价格

Solved A cement grinding mill “A” with a capacity of 50 tons - Chegg

A cement grinding mill “A” with a capacity of 50 tons per hour utilizes forged steel grinding balls costing P12,000 per ton, which have a wear rate of 100 grams per ton cement milled. Another cement mill “B” of the same capacity uses high chrome steel grinding balls costing P50,000 per ton with wear rate of 20 grams per ton cement milled.

获取价格

Ball Mill Design/Power Calculation - 911Metallurgist

2015/6/19 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum and finally the type of

获取价格

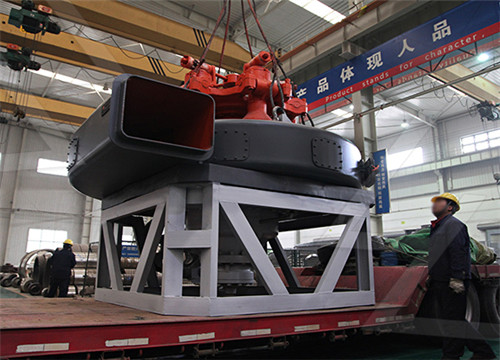

BALL MILLS Ball mill optimisation - Holzinger Consulting

2021/3/12 and cement. Roller presses are used mainly in combination with a ball mill for cement grinding applications and as finished product grinding units, as well as raw ingredient grinding equipment in mineral applications. This paper will focus on the ball mill grinding process, its tools and optimisation possibilities (see Figure 1). The ball mill

获取价格

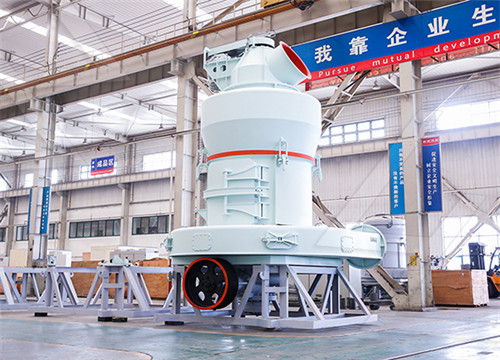

Cement Ball Mill - Cement Grinding Machine

Cement ball mill is a cement grinding machine used in the cement production line for cement clinker grinding. AGICO supplies the cement ball mills for processing limestone, cement clinker, gypsum, slag, ore, etc. ... Capacity (t/h) Feed

获取价格

Energy and cement quality optimization of a cement grinding circuit

2018/7/1 The model structure for the one-chamber or multi-chamber cement ball mills have been subject of various researchers. Benzer et al. [21] developed model for open circuit two-chamber cement ball mill. In their structure, the first and second chamber of the ball mill as well as the intermediate diaphragm were all model fitted hence calibrated with ...

获取价格

Calculations for design of ball mills for cement grinding

2024/10/13 1) Ball mill design requirements - The first step in ball mill sizing is to determine what design requirements should be met by the ball mill. This will depend on the type of cement being ground and the specific application requirements of the ball mill. 2) Capacity - The second step is to calculate the capacity required by the ball mill.

获取价格

cement mill capacity calculator - -china

cement mill capacity calculation – Ore Machine China, cement mill capacity calculation . is the biggest manufacturers in Aggregate Processing Machinery for the sand,quarry,mining,construction and recycling ... Go to Product Center.

获取价格

cement ball mill capacity calculation – Grinding Mill China

MathCement Module 1 MathCement 2000 Volume-1 : Cement plant Calculation of Power at Ball Mill Shaft for Raw Material,based on Bond Clinker grinding mill – calculation of capacity and power MC_V1_B210_Cement_13_r2 » Free Online Chat. The cement mill. brief description of a cement mill. Cement clinker is usually ground using a ball ...

获取价格

calculation of cement ball mill capacity – Grinding Mill China

ball mill capacity calculation,price of ball mill for talc . ball mill capacity calculation.To make the ball mill operate good, we must strictly abide by the Ball Mill; Cement Ball Mill; Ball mill for lime slaking systems; Ball mill » Free Online Chat Cement mill – Wikipedia, the free encyclopedia. This gives good cement performance, and reduces energy consumption by 20-40% ...

获取价格

How can I calculate cement ball mill capacity? - WinnerMac

2023/5/24 The capacity of a cement ball mill can be calculated using the formula: C = (k * Q)/(p * S * G) Where C is the capacity of the mill in terms of actual tonnage of material that can be ground per hour, k is a constant representing the grinding efficiency, Q is the volumetric flow rate of feed to the mill, p is the density of the material being ground, S is the specific gravity of the

获取价格

cement ball mill design capacity calculation - Grinding Mill

2021/7/14 cement ball mill capacity calculation in Madras, Tamil . Posts Related to cement ball mill capacity calculation in Madras, Tamil Nadu, South Africa. Ball mill for lime design ball mill solution in Philippines, » More detailed!

获取价格

cement mill volume calculation - lamelanzana

A 1.5 mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been operating with satisfactory performance in-terms of system availability and output, however power consumption was on higher side. 3.1 System Description Mill Rated capacity 150 t/h OPC at

获取价格

Heat balance calculators - thecementgrindingoffice

2018/11/17 - The second method, we know the ventilation inside the mill + the quantity of water injected and we calculate the temperature of the cement at mill outlet. In this calculation, the user needs to re-type the cement temperature found by

获取价格