أرسل لنا رسالة

Working principle and maintenance of mbz2136 rod mill

2136棒磨机说明书 - 道客巴巴

2012/12/13 2136棒磨机说明书. 下载积分: 840. 内容提示: 说 明 书 MBG2136 周边排矿棒磨机 中国京冶工程技术有限公司 2011 / 5 /.

获取价格

The Working Principle and Structure of Rod Mill

2019/10/17 In this post, we're going to learn more about rod mill. We'll cover it from two aspects: 1. Working principle. 2. Structure. Let's dive right in! 1. Working Principle of Rod Mill. Rod mill is a common equipment for grinding

获取价格

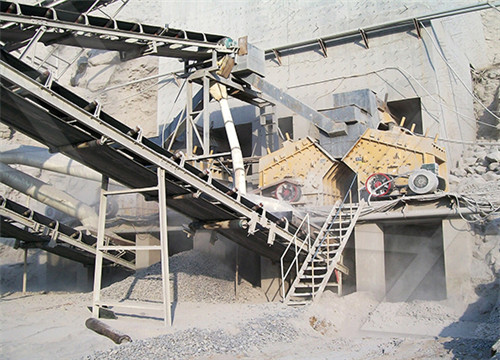

Rod Mills: Efficient Grinding Solutions for Mining

Rod Mill Capacity and Sizing TableRod Mill SpecificationsRod Mill CapacitiesRod Mill General Arrangement-DimensionsPeripheral Discharge Rod MillsWet Grinding Rod MillingDry Rod Mill GrindingCenter Peripheral Discharge Rod MillRod Mills may be considered either fine crushers or coarse grinding equipment. They are capable of taking as large as 2″ feed and making a product as fine as 35-48 mesh. Of particular advantage is their adaptability to handling wet sticky ores, which normally would cause difficulty in crushing operations. Under wet grinding conditions of course the...

AMIT 135: Lesson 8 Rod Mills – Mining Mill Operator Training

Introduction of Rod Mill Working Principles or Operation

2016/4/20 Here is some introduction of rod mill working principles or operation. Rod mills are suitable for coarse grinding operation. Rod mill operation are as follow. With asynchronous

获取价格

Rod Mill - SpringerLink

2023/5/3 Therefore, rod mill has the function of selective grinding, and its products are uniform in particle size and overgrinding is slight. The rod mill is mainly used for gravity or

获取价格

Rod Mill Maintenance: Tips for Longevity and Performance

2024/10/30 Investing in proper maintenance practices not only extends the life of rod mills but also leads to improved product quality, reduced operational costs, and a safer working

获取价格

What is a Rod Mill? - ball mills supplier

A rod mill is a type of ore grinding equipment used to grind materials into fine powder. Unlike ball mills, rod mills use long steel rods instead of balls as the grinding medium. Rod mills are ideal

获取价格

The Working Principle and Advantages of the Rod Mill

The working principle of the rod mill makes the rod mill suitable for many large industries or production lines. In order to avoid the harm caused by over crushing, the rod mill is often used

获取价格

Structure, Working Principle, and Application Fields of Rod Mill

2023/10/7 Working principle of rod mill. After understanding the structure of the rod mill, we will delve deeper into its working principle. The rod mill mainly completes the grinding process

获取价格

Rod Mill, Rod Mill Manufacturers, Rod Mill Working Principle, Rod ...

[Introduction] : Rod mill is a grinding equipment with steel rod as medium [Capacity] : 0.62~250t/h [Improvement] : Xinhai rod mills include overflow rod mill, end peripheral discharge rod mill and center peripheral discharge rod mill, which could meet different requirements.

获取价格

Rod Mills: Efficient Grinding Solutions for Mining

2016/6/1 Maintenance of the center peripheral discharge mill is definitely much lower than that of any other sand manufacturing machine. The greater portion of the wear which takes place is on the inexpensive high carbon steel

获取价格

MISHRA DHATU NIGAM LIMITED (MIDHANI) BAR

2023/12/16 Wire Rod Mill: Drawing 28785-000-000-PRR-0001, Rev.0 - Wire Rod Mill – Proposed Mill Layout The layout and equipment described in this specification are representative of present ideas. 1.3 The Tenderer shall note that the Wire Rod Mill will be located in

获取价格

Automation and Control in Wire Rod Mill – IspatGuru

2023/3/20 A magnetic contact-less sensor forms the core of the system. It is sturdy and compact and is designed to be maintenance and wear free. The working principle of the sensor is based on detection of the eddy currents, generated on the surface of the rolled stock by a variable electro-magnetic field.

获取价格

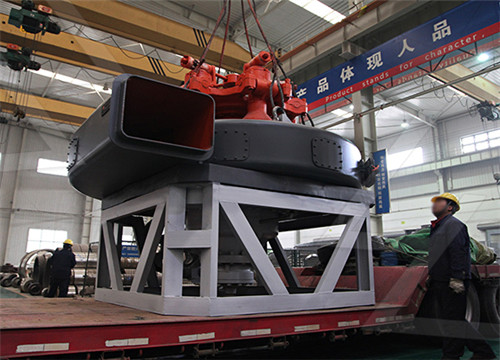

Rod Mills Grinding Mills DOVE

2024/11/12 DOVE Rod Mills are supplied in a wide range of capacities and specifications. DOVE supplies 2 models of small Rod Mills designed for laboratories milling process, capacity range of (5000g/Hr – 20 Kg/Hr). For small to large scale grinding operations, DOVE Rod Mills are supplied in 15 models, capacity range of (1.5 TPH – 580 TPH).

获取价格

classifications and working of mills in a power plant PPT

2020/6/29 6. TYPES OF COAL PULVERIZER • Tube or ball mills: Low-speed machines that grind the coal with steel balls in a rotating horizontal cylinder. If the diameter of the cylinder is greater than the length of the cylinder, the mill is called a ball mill. If the length of the cylinder is greater than the diameter of the cylinder, it is called a tube mill.

获取价格

The Working Principle and Structure of Rod Mill

Working Principle of Rod Mill. Rod mill is a common equipment for grinding operation in mineral concentrator, which is mainly suitable for rough grinding operation. Is through asynchronous motor reducer with small gear coupling, the surrounding big gear reduction drive under its impetus, drive the rotary rotate, cylinder body is equipped with ...

获取价格

The Working Principle of Raymond Mill PDF Free

2023/8/22 1. Understanding Raymond Mill's Working Principle Raymond Mill has established itself as a renowned grinding equipment in various industries, revolutionizing material processing and setting new standards for efficiency and performance. The Working Principle of Raymond Mill is based on the pendulum grinding principle. Here is a step-by-step breakdown

获取价格

Rod Mill Design Calculations - 911Metallurgist

2018/4/5 For equation 12, use the Work Index from a rod mill grindability test, since this more represents the coarse fraction of the feed; if not available then use the ball mill grindability test results. EF5 – Fineness of Grind Factor – this applies to fine grinding when the 80% passing size of the product is finer than 75 micrometers (200 mesh ...

获取价格

What Are the Differences between Ball Mill and

2023/2/15 Rod mill. According to the discharging way, rod mills can be divided into three types: center and side discharge type, end and side discharge type, and overflow type. a. End and side discharge rod mill. This kind of rod

获取价格

Maintenance and Overhaul of Rod Mill - Luoyang Dahua

2021/8/20 9. The steel rod is added in time according to the wear. 10. If abnormal conditions are found, stop the repair immediately. The maintenance of the mill is a regular work, and the quality of the repair work directly affects the operating rate and service life of the rod mill.

获取价格

Hammer Mill – Principle, Construction, Working,

2022/8/29 Principle of Hammer Mill: It is a size reduction equipment where stresses of varied nature are applied to achieve size reduction. Term size reduction is a process in which particles of solid are broken or cut into smaller

获取价格

Ball Mill Grinding Machines: Working Principle, Types, Parts ...

Ball Mill, Working Principle, Types, Parts, Applications and Advantages. Ball Mill Grinding Machines: Exploring the Working Principle, Types, Parts, Applications, Advantages, and Recent Developments. Ball mill grinding machines are widely used in various industries for the comminution of materials into fine powders.

获取价格

Understanding the Working Principle of a Raymond Mill

Introduction: A Raymond mill whizzer, also known as a classifier, is an essential component in the Raymond mill system. It plays a crucial role in the separation of finished products based on their sizes and grades. In this article, we will delve into the working ...

获取价格

Bar mill and wire rod mill optimization - ABB Group

Bar mill and wire rod mill optimization: profile rolling process goes digital Harness high level plant and process data and use it to trace and visualize the KPI’s important to your profile rolling mill, right down to individual billet precision.

获取价格

Construction and Working of Ball Mill - Solution Parmacy

2021/5/11 Tube mill can grind finer products than the conventional ball mill. Their construction is also simple and generally used for grinding hard material. Tube mill has a higher length/ diameter ratio as compared to Ball mill. Rod mill: This is a modification of the tube mill. Instead of balls or pebbles, rods are used as grinding material.

获取价格

How to Operate and Maintenance of The Rice Mill

2023/12/6 Make a Quick Inquiry Now ! 1. Selection of Rice Mill Machine. The use of a rice mill machine depends on the variety of brown rice and the quality requirements of the finished product. Generally, the iron rod rice machine can be used for processing hard rice, and the emery roller rice mill should be used for processing soft rice, preferably a vertical emery roller.

获取价格

Working principle and characteristics of vertical mill

2024/10/13 The working principle of a vertical mill involves the rotation of a grinding table with rollers attached to it. Raw materials are fed into the table and ground between the rollers and table. ... One disadvantage of the vertical mill is that it may require more frequent maintenance due to the complexity of its design. However, this can be ...

获取价格

Rod Mill - SpringerLink

2023/5/3 Center Periphery Discharging Rod Mill. The center periphery discharging rod mill feeds the material through the journals at both ends of the mill, and discharges the grinding products through the circular orifice in the middle of the cylinder (Fig. 3).Ore pulp is characterized by short stroke, steep slope, and it can be coarsely ground with fewer fine particles and low

获取价格